Frequently Asked Questions

-

Why do badges take four to six weeks to receive?

Each badge is made to order and goes through a minimum of 27 manufacturing steps with many badges requiring over 40. We use highly sophisticated software to efficiently manage production so that we can get your badge on its way to you in an average of 20 working days (4 weeks). To allow for processing, shipping and the possibility of a few extra days in production, we advise customers to allow up to 6 weeks for delivery.

Rush production service is available for a fee.

-

Is rush production service available?

We do have a rush program available that guarantees production within 5, 10, or 15 business days. The program provides a guaranteed ship date at the time you place your order. If you require rush production, please contact your dealer to confirm the availability of the service for your specific order, and for a quote.

-

Can I purchase a badge directly through Smith & Warren?

All Smith & Warren products are sold through our extensive network of authorized dealers and distributors. Consult our Dealer Locator to find a dealer near you or for a list of online dealers. If you are a Federal or Military agency feel free to visit our GSA Schedule Contract page for more information.

-

What are Smith & Warren's finishes?

Standard Finishes

Nickel Electroplate

The most economical silver tone finish, nickel electroplate, provides a high degree of durability without a high price but may lose some luster with age.

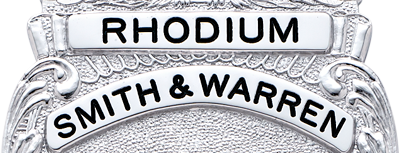

Rhodium

A bright and brilliant silver tone finish that will not tarnish; a great combination of shine and durability.

Gold Electroplate

A pure 24K gold electroplated finish applied over a nickel base provide a gold finish that is tarnish-resistant, but may show some wear over time.

Premium Finishes

Sil-Ray

Heavy silver tone electroplated layers combined with our extremely hard protective coating produce a brilliant finish that will stand the test of time.

Gol-Ray

The most durable gold finish, combining heavy electroplated layers of 24K gold with an extremely hard protective clear coat, the result is a gold finish that outshines the competition.

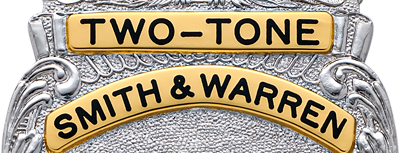

Two-Tone

The best of both worlds, Gol-Ray™ and Sil-Ray™ combine to form a two tone finish that is bright, durable and consistent.

Cote D'Or

The ultimate fine gold finish, our thickest layer of 24K gold plate and our ultra durable clear coat, provides a presentation quality finish; an excellent choice for awards, gifts and display badges.

-

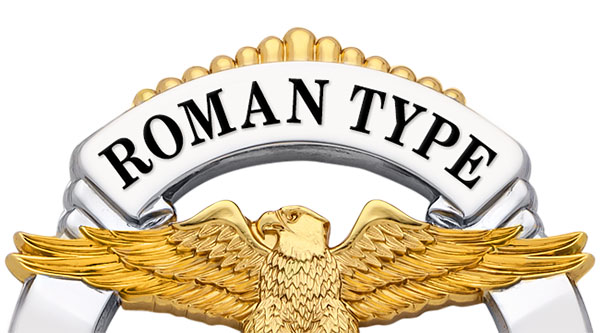

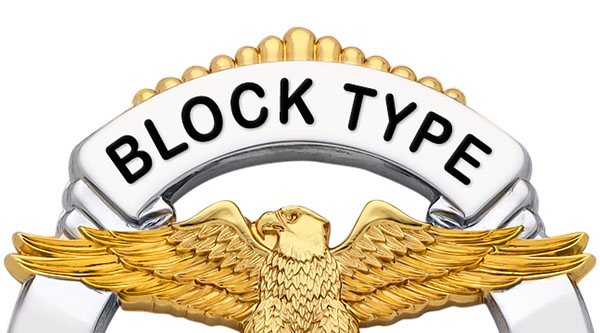

What fonts are available for engraved lettering?

All Smith & Warren badges are available in Roman or Block Font.

Roman Font

Block Font

-

What is the difference between Hard and Soft enamel?

Smith & Warren badges are available with 2 types of enamel.

Soft, or regular enamel is included on Nickel, Rhodium, and Gold Electroplate badges. This type of enamel is applied to the badge, and baked under low heat. The indentations of the engraved letters can be felt after the enamel is applied.

Hard fired cloisonne enamel is a baked glass that is applied to the lettering on the badge. The enamel is baked at a high temperature (to melt the glass), cooled and then hand stoned flush to the level of the surrounding metal. When finished, the letters are smooth to the touch and level with the surrounding metal. Hard enamel is included with Sil-Ray, Gol-Ray, Two Tone and Cote D'Or Badges.

-

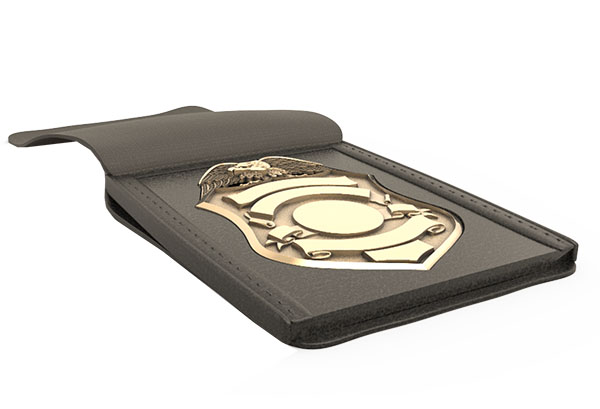

When would I choose a flat badge vs. a curved badge?

Flat

Flat badges are often selected when the badge is going to be placed exclusively in a leather case like a wallet, credential case or belt clip holder. Flat badges are also ideal for badges that are ordered for display purposes.

Curved

The curved option is often used for badges that will be worn on a uniform. The curve combined with the pin & safety catch attachment keeps the badge steady when worn.

-

What is the difference between solid back badges and shell back badges?

Some Smith & Warren badges are available in solid or shell back versions. While there is no difference in quality or durability, shell back badges are lighter than their solid back counterpart.

Shell Back

Solid Back

-

What is a text separator?

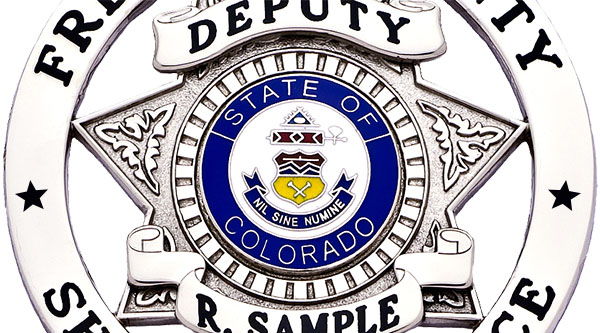

All Smith & Warren badges featuring a circular panel can have stars or dots engraved to seperate the lettering on the top and bottom of the panel as show below.

Star separators

Dot separators

-

What types of attachments and fasteners can I order with my badge?

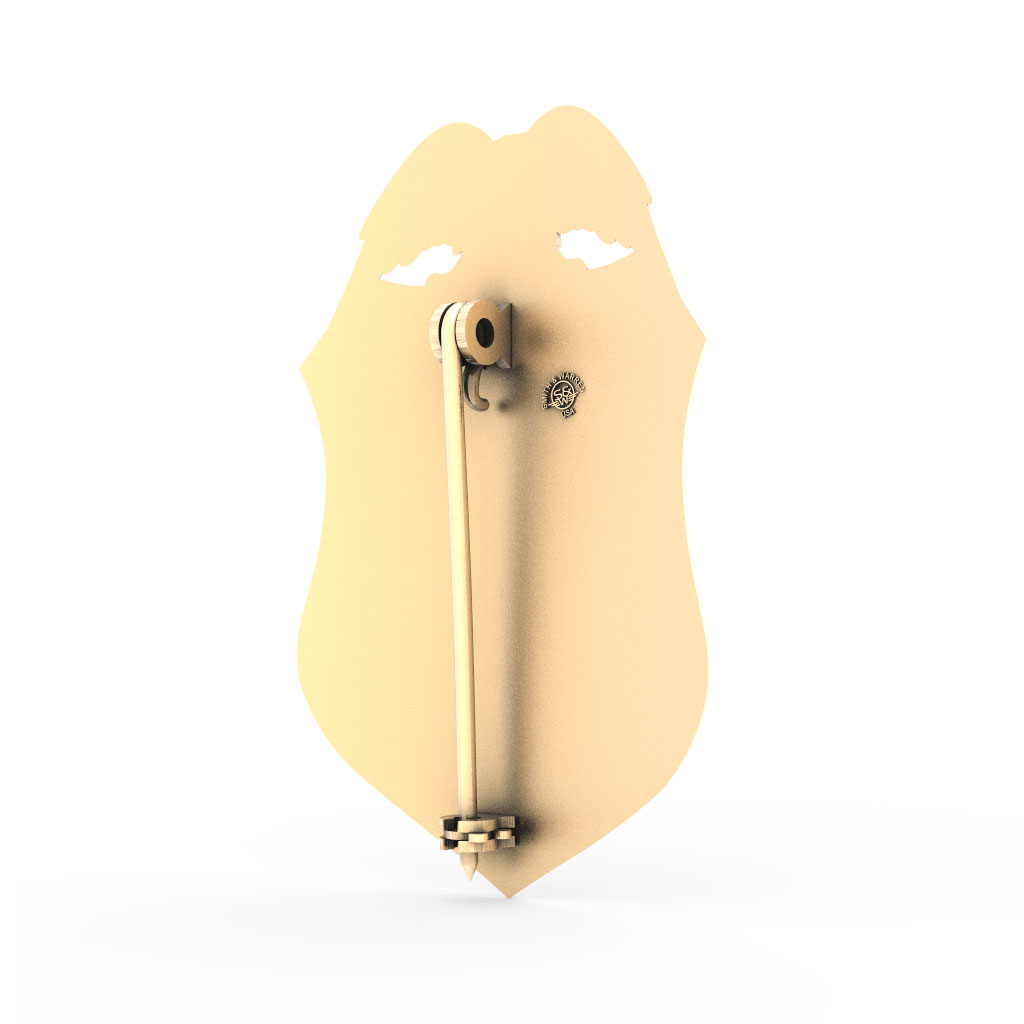

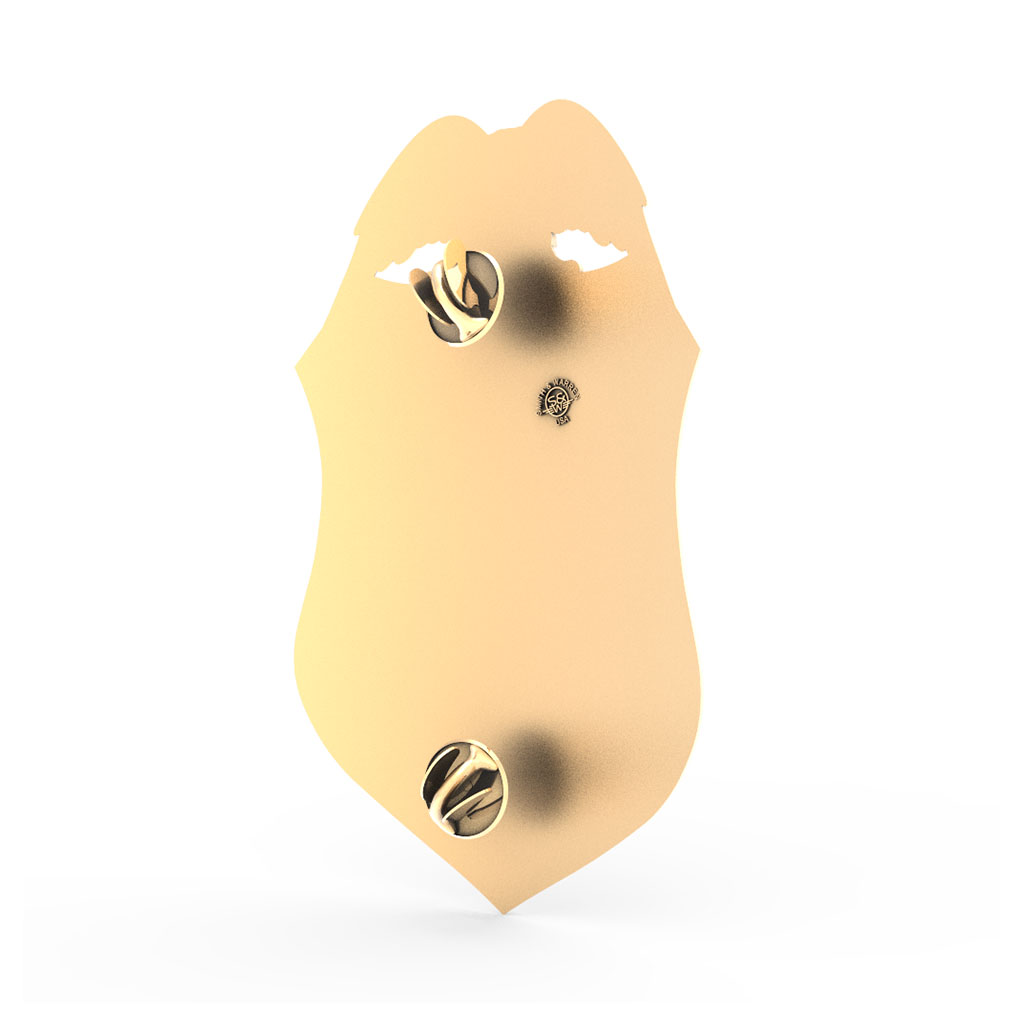

Pin & Safety Catch

Select the Pin & Safety Catch attachment if you are pinning your badge on your uniform or attaching it to a belt clip holder. This is also a popular attachment if attaching insignia to an epaulet.

Clutch Back

Select the clutchback attachment if you are attaching your badge to a uniform shirt that cannot accommodate a pin & Safety catch. Clutchback is the most popular attachment for uniform insignia and collarbrass.

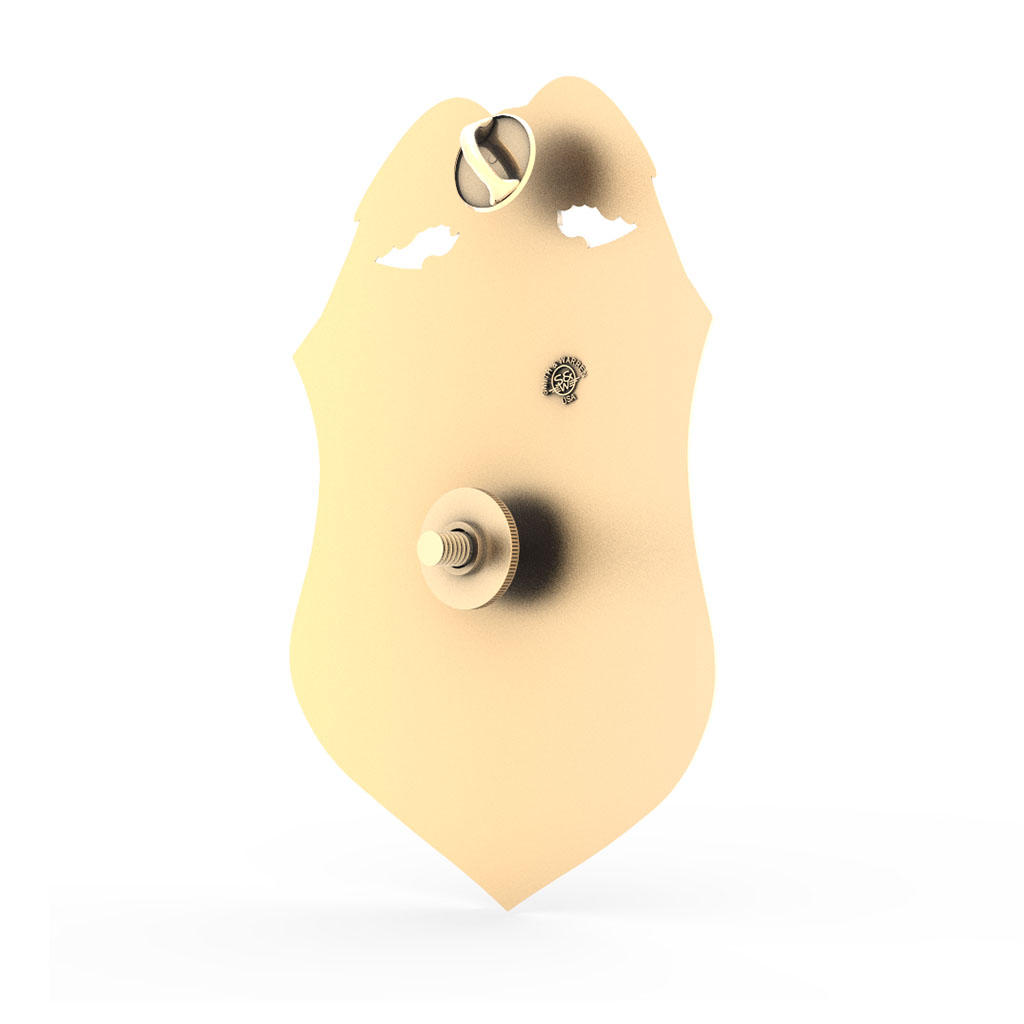

Screwback with pin

Select the Screwback attachment if you will be attaching your badge to a hat. Screwback is also popular if putting your badge on a wooden plaque or in a shadow box. Screwback attachment is incompatible with wallets, ID cases, or belt clip holders.

Wallet Clip

Select the Wallet Clip attachment if you are putting your badge in a wallet or ID case. Wallet clip attachment is not compatible with belt clip holders.

No Attachment

Select None (No Attachment) if your application does not require anything on the back of your badge. This is popular for customers who plan to mount the badge on a plaque or use adhesive to attach it into a carrying case.

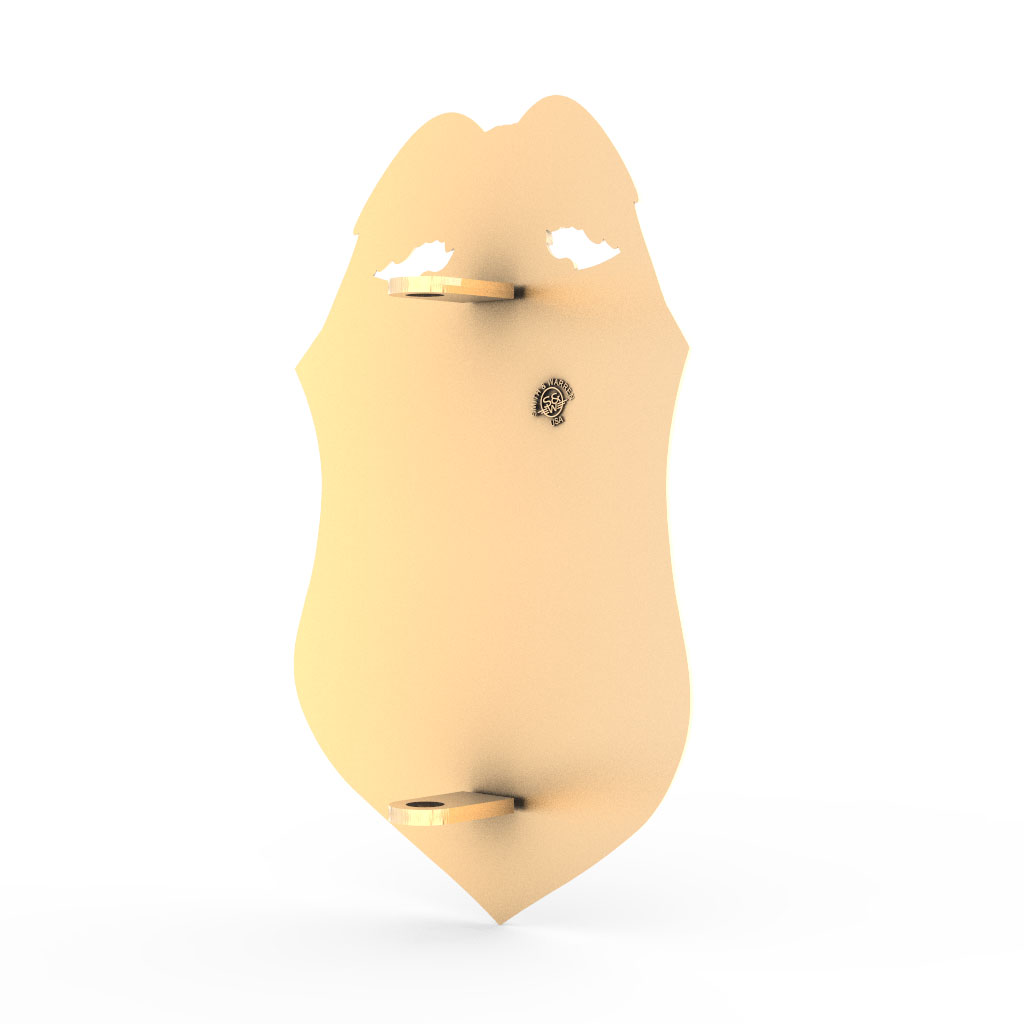

Lugs

Select Lugs only if your uniform is designed to accept it. This is a very unique attachment that is commonly used in the mid-Atlantic region, but very rarely outside that geographic area. Lugs are not compatible with leather accessories.

Glue in Leather

Select Glue in Leather for the best attachment option for carrying your badge in a leather accessory. Your badge will be professionally mounted into the recess of your leather ID case, wallet, belt clip, or neck chain holder. This attachment method provides the lowest profile of any attachment option when combining a badge and leather accessory to a wallet. Leather accessories are sold separately.

-

Warranty Repair and Refinishing - Common Questions

Q: Do I need a Return Authorization?

A: Yes. Please do not send your badge into the factory without first obtaining a return authorization. You can request your return authorization HERE.Q: Do all scratches get removed when refinishing the badge?

A: Your badge will be lightly polished before the new finish is applied. During this process only shallow scratches will be removed, but the deeper scratches will remain. To remove a deep scratch requires polishing down below the depth of the scratch. Removing this much material from the surface of your badge will also remove details and generally degrade the badge.Q: Do all repairs require that refinishing be done?

A: Not all repairs require refinishing of the badge. Certain repairs can be completed without having to strip and refinish the badge. Refinishing will only be done if required to complete the repair or if you request it.Q: Will my badge come back in new or "like new" condition after I send it in for a refinishing?

A: Your badge is going to come back with a fresh surface finish. It will be cleaned, tuned and ready for continued use, but it will not be a new badge. Repair and refinishing is not the same as refurbishing. Some types of blemishes and scratches that your badge gets over time are permanent and cannot be removed through the refinishing process.Q: How long do repairs take?

A: If the badge you are sending to us for repair is less than 1 year old, then the repair will be completed within 5 business days of receipt at the factory. If the badge is over 1 year old, then it will depend on the type of repair. Repairs that do not require refinishing are typically shipped back within 5 business days. Repairs that require refinishing typically take 4 to 6 weeks.Q: Can you change wording on a badge?

A: Engraving is permanent. We cannot change wording on a badge during the repair process.Q: Can I make changes to the badge when I send it in for repair? (i.e. Change seal, finish, etc.)

A: Under our warranty program no changes can be made. We can only repair a badge to the originally ordered specifications. If you would like a quote on making modifications to the badge (change of seal, soft enamel lettering color, finish, etc.) please contact us.Q: Can hard enamel be repaired if it cracks?

A: Hard enamel is a glass enamel. Cracks in glass are permanent. If the glass is broken we will do our best to repair it with a similar colored epoxy resin to make it look better.

Q: My badge is bent. Can you fix it?

A: If your badge is very slightly bent due to normal wear and tear we may be able to restore the original shape. If your badge is more than slightly bent it is unlikely the shape can be restored under our warranty service.Q: Can you replace a panel if it falls off?

A: Yes. If your panel falls off, then we can re-attach or replace it with the same wording that was originally there.Q: Can you replace a seal if it falls off or is damaged?

A: Yes. If your seal detaches we will replace it. We can only replace it with the original seal though.Q: Do you issue a prepaid shipping label for repairs?

A: If your badge requires repair due to a manufacturer defect within 12 months of being shipped from the factory, then we will send you a prepaid shipping label along with the return authorization. For other repairs you are responsible to get the badge to us. We recommend using a trackable service.Q: What happens if my badge gets lost in transit on the way to the factory?

A: We are not responsible for lost packages. We highly recommend using an insured and trackable service when sending in your badge. To avoid losses in transit also make sure your badge is properly packaged. Always use a box or bubble pack. Never ship a badge in a standard envelope.Q: My badge is in a leather case. Should I send it as well?

A: Generally the answer is no. If you can remove the badge please do so before sending it in. If the badge is permanently mounted, then you can send it to us in the case. We will remove it and then remount it in the case before sending it back.Q: Are leather cases covered under the same warranty as badges?

A: No. Leather items are only covered by a 1 year warranty covering only manufacturer defects.Q: Are insignia covered by the same warranty as badges?

A: No. Insignia items are covered by a 1 year warranty covering only manufacturer defects.Q: Are nameplates covered by the same warranty as badges?

A: No. Nameplates are covered by a 1 year warranty covering only manufacturer defects.