What’s the difference between Hard Enamel and Soft Enamel?

Understanding the differences of hard and soft enamel in custom badges.

Are you uncertain about which enamel type to choose for the lettering on your badge? Considering an upgrade to hard enamel but wondering how it differs from soft enamel? At Smith & Warren, we frequently address questions about enamel. So, what is the difference between soft and hard enamel?

In short, Soft Enamel is paint, and Hard Enamel is glass. Soft enamel lettering looks indented, while hard enamel lettering looks like it is flush with the surface of the panel.

In this article, we are going to explore how these two enamels are applied to badges, any price differences, and their durability. By the end of this article, you should be able to make the best decision for you or your department when it comes to enamel for your badge.

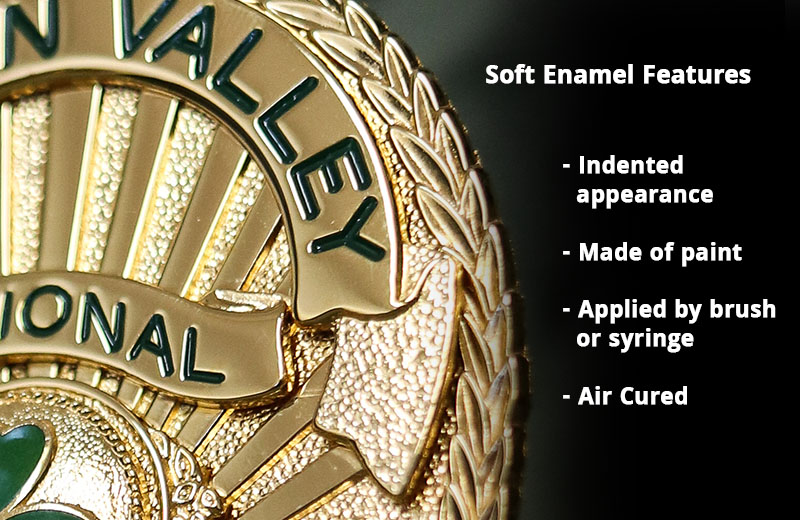

What is Soft Enamel lettering?

Soft enamel is a paint that is applied into the lettering of your badge. It is applied using either a brush or a syringe and then air-cured. This enamel process gives the lettering on your badge an indented appearance. Some customers will call it “engraved lettering” because after the enamel is applied, the letter still looks like it was engraved into the surface of the badge.

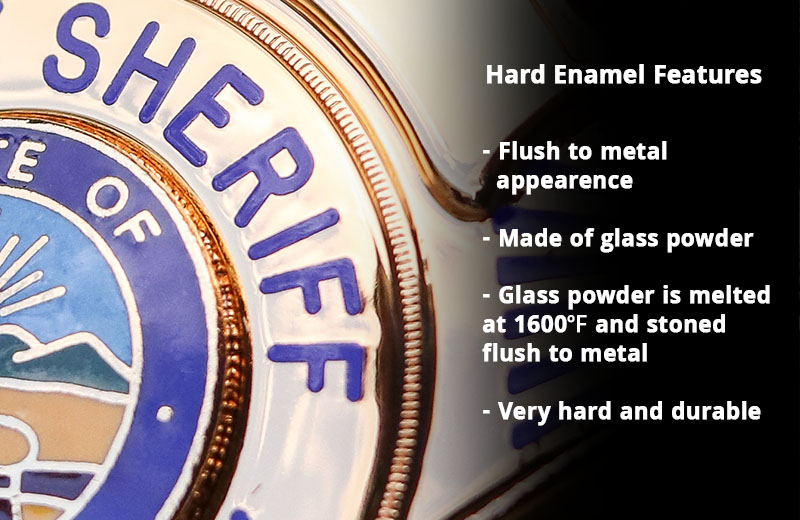

What is Hard Enamel lettering?

Hard Enamel is also known as “Cloisonne Enamel” or “Hard-Fired Enamel.” Hard Enamel is a process whereby glass is fused to metal. When applying this labor-intensive process to a badge, each letter is filled with finely ground glass powder. The glass powder is then melted in a kiln at over 1600 degrees Fahrenheit. The excess glass is then stoned down to the surface of the panel, and finally, the surface of the glass is fired one more time to give it a shiny “glazed” appearance. Hard Enamel makes the letter appear to be flush with the surface of the badge. Some customers even think it is printed on the surface, but it is not.

Does one cost more to get than the other?

Hard enamel is a very labor-intensive process and, therefore, does cost more. The price range depends on the manufacturer, but at Smith & Warren, soft enamel is included with standard finish badges (Nickel, Rhodium, or Gold Electroplate) with the option to upgrade to hard enamel for $15. Alternatively, hard enamel comes included with our deluxe finish badges. (Sil-Ray, Gol-Ray, Two Tone, and Cote D'Or Badges).

How can you tell the difference on a custom badge?

To quickly differentiate between the two enamel types, complete a simple test. Gently run your fingertip over the lettering on the badge. If the lettering feels grooved or indented, it's likely soft enamel. Conversely, if the lettering looks and feels flush with the surface, then you’re holding a hard enamel badge.

What type of enamel is better for custom badges?

Hard enamel is widely considered to be the best type of enamel for badges due to its strength and durability. Hard enamel is very hard (only a diamond can scratch it), making it hard to scratch and crack. It is also resistant to UV light damage and color fading, making it the superior choice for badges.

Soft enamel comes in two ways: water-based or oil-based. Oil-based is superior to water-based because it's not water-soluble. At Smith & Warren, we use oil-based soft enamel so that the enamel holds up well when the badge is used outdoors. If ordering soft enamel, it is a good idea to ask the manufacturer if it is oil or water-based.

Does Hard Enamel add manufacturing time to my badge order vs. Soft Enamel?

The answer to this question varies between manufacturers. Hard enamel requires more steps than soft enamel. Most manufacturers quote extra time for a badge (typically 1 to 2 weeks additional) for a badge with hard enamel.

Which enamel type is right for your custom badge?

The choice between soft and hard enamel often comes down to personal preference. Ultimately, you want to pick the type of enamel that you like the look of. In our experience, some customers prefer the indented "soft" look over the flush "hard" enamel and vice versa.

If you have any questions or concerns about choosing the right enamel for your badge, please contact us. We're here to help you make the best decision for your badge.

Recommended articles in our Learning Center

How long does it take to make a custom badge?

How much do custom badges cost?